Metals play a critical role in modern industries, from construction and aerospace to automotive and medical equipment. While many metals exist, only a few can withstand extreme conditions such as high pressure, heavy loads, and extreme temperatures. Engineers and manufacturers constantly seek materials that offer the perfect combination of strength, durability, and resistance to wear. In this article, we explore the top 10 strongest metals used in high-stress applications, focusing on their properties, uses, and why they are chosen for the most demanding environments.

Understanding Strength in Metals

Before diving into the list, it’s important to understand what makes a metal “strong.” Strength in metals can refer to different aspects:

- Tensile strength: the maximum stress a metal can withstand when being pulled apart.

- Compressive strength: the ability to resist being squashed or compacted.

- Yield strength: the stress at which a metal begins to deform permanently.

- Hardness: resistance to indentation, scratching, or wear.

Metals chosen for high-stress applications usually combine high tensile strength, durability, and resistance to extreme conditions like heat, corrosion, and pressure.

The Top 10 Strongest Metals

Tungsten

Tungsten is often regarded as the strongest natural metal, with an incredibly high tensile strength of around 142,000 psi. It also has the highest melting point of any metal at 3,422°C, making it suitable for applications that involve extreme heat. Tungsten is widely used in aerospace, military projectiles, and industrial equipment where durability is non-negotiable. Its brittleness, however, limits its flexibility.

Titanium

Titanium is highly valued for its balance of strength and low density. It is about 45% lighter than steel but almost as strong, making it ideal for aerospace structures, submarines, and medical implants. Its corrosion resistance further enhances its usefulness in harsh environments. With a tensile strength of around 63,000 psi in its pure form and even higher in alloys, titanium is one of the most versatile options in the top 10 strongest metals.

Chromium

Chromium is best known as the key component in stainless steel, giving it hardness and corrosion resistance. It has a tensile strength of 94,000 psi and is used in plating to provide protective coatings on tools, automotive parts, and industrial equipment. While brittle in its pure state, chromium’s combination with other metals creates durable and strong alloys perfect for high-stress conditions.

Steel Alloys

Although steel is technically an alloy of iron and carbon, it remains one of the most used and strongest materials in modern industry. Advanced steel alloys, such as maraging steel, reach tensile strengths of up to 300,000 psi. These alloys are designed to handle high stress, making them essential in construction, defense, and aerospace engineering. Their combination of affordability, strength, and machinability ensures steel alloys maintain a key place in this list.

Inconel

Inconel is a nickel-chromium-based superalloy known for its incredible ability to retain strength even at extremely high temperatures. With tensile strengths exceeding 150,000 psi, Inconel is commonly used in jet engines, gas turbines, and nuclear reactors. Its resistance to oxidation and corrosion makes it indispensable for applications where ordinary metals would fail under high stress and heat.

Titanium Alloys

Pure titanium is strong, but titanium alloys, such as Ti-6Al-4V, are significantly stronger. With tensile strengths up to 200,000 psi, these alloys are widely used in aerospace, biomedical implants, and automotive racing industries. They combine lightweight properties, biocompatibility, and exceptional durability under stress, making them highly valuable in specialized applications.

Osmium

Osmium is one of the densest elements known, and it ranks high among the hardest metals. Though brittle, its alloys with other metals make it incredibly strong and durable. Osmium is commonly used in electrical contacts, fountain pen tips, and instrument pivots. While its rarity and brittleness limit its widespread use, its hardness ensures it remains relevant in precision and high-stress environments.

Iridium

Iridium is one of the most corrosion-resistant metals, capable of withstanding extreme conditions that would destroy most others. With a high melting point of 2,446°C and impressive hardness, iridium is used in spacecraft components, deep-sea cables, and medical devices. Its strength and durability under high stress make it one of the rare but vital metals for specialized applications.

Vanadium

Vanadium is not exceptionally strong on its own, but when alloyed with other metals, it dramatically increases strength and durability. Vanadium steel, for example, is both tough and lightweight, with widespread use in aerospace, automotive, and construction industries. Its tensile strength in alloys can exceed 120,000 psi, making it a valuable addition to the top 10 strongest metals.

Tantalum

Tantalum is known for its resistance to corrosion, particularly from acids, and its strength in high-stress conditions. With a melting point of 3,017°C and excellent ductility, tantalum is used in electronics, aerospace components, and surgical instruments. It combines strength and resilience, making it suitable for extreme environments where other metals fail.

Applications of the Strongest Metals

The top 10 strongest metals are used across multiple high-stress industries.

- Aerospace: Titanium alloys, Inconel, and steel alloys are essential in building aircraft frames, engines, and space exploration equipment.

- Construction: Steel alloys and vanadium-strengthened steel provide the durability required for skyscrapers, bridges, and tunnels.

- Medical field: Titanium and tantalum are crucial for implants, surgical tools, and biomedical devices due to their strength and biocompatibility.

- Defense and military: Tungsten, titanium alloys, and steel alloys are used in armor, projectiles, and combat vehicles.

- Energy sector: Inconel and iridium withstand extreme temperatures and corrosion in turbines, reactors, and drilling equipment.

Conclusion

The strength of a metal is not just about its ability to withstand force, but also about how well it performs in extreme environments without failing. The top 10 strongest metals—tungsten, titanium, chromium, steel alloys, Inconel, titanium alloys, osmium, iridium, vanadium, and tantalum—are indispensable in industries that demand reliability and resilience. Each has unique properties that make it suitable for specific high-stress applications, from aerospace to medicine. As technology continues to advance, these metals will remain at the core of innovation, ensuring safety, durability, and performance in the world’s most challenging environments.

More Stories

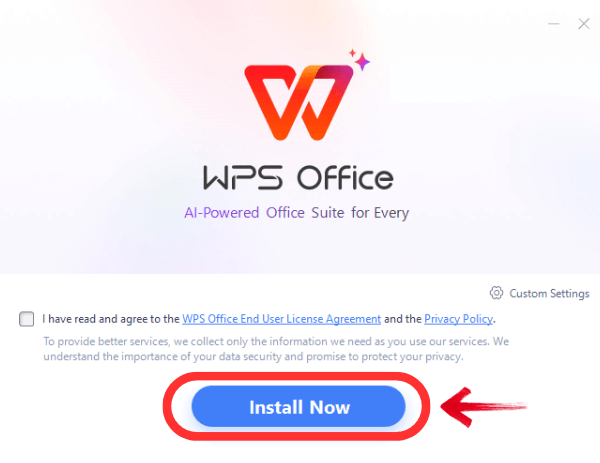

A Step-by-Step Guide to Using WPS Effectively

Boost Team Performance with WPS Tools

Getting Started with WPS Download: Your Complete Guide to WPS下载 Today